When a hydraulic system starts leaking, the root cause often seems mysterious—until you take a closer look. The truth is, almost every component in a hydraulic circuit is vulnerable to leaks if not properly engineered or maintained.

From piston seals to fittings to pipe plugs, leaks are a symptom of the system’s weakest link. But by understanding where leaks originate and why, you can design systems with tighter seals, longer life, and better performance.

Where Do Hydraulic Leaks Happen?

Some components are simply more prone to leakage than others. Here are the most common offenders:

- Piston rod seals: These seals are designed to contain high-pressure hydraulic fluid while still allowing a thin lubricating film to form along the piston rod. That balancing act often leads to slow weeping leaks—especially if the rod becomes scored or the seal begins to degrade.

- Hydraulic fittings: Every hydraulic system includes dozens—if not hundreds—of fittings: SAE fittings, ORB fittings, metric fittings, and more. Each connection is a potential leak path, especially when mismatched fittings or improper torques are involved.

- Hydraulic plugs: Plugs are used to block unused ports in valves, manifolds, and piping systems. Unlike elbows or tees, plugs don’t benefit from stabilizing pipe runs and are more likely to loosen over time due to vibration, thermal cycling, or pressure shocks.

Why Plugs Are a Major Source of Leaks

Traditional hydraulic plugs often back out of position, especially in dynamic environments. Without support from connected piping or anchors, they absorb mechanical shocks and vibration directly. Eventually, these forces overcome the plug’s thread friction and allow it to wiggle free—leading to persistent hydraulic leaks that are difficult to detect until damage has been done.

The Zero-Leak Gold® Advantage

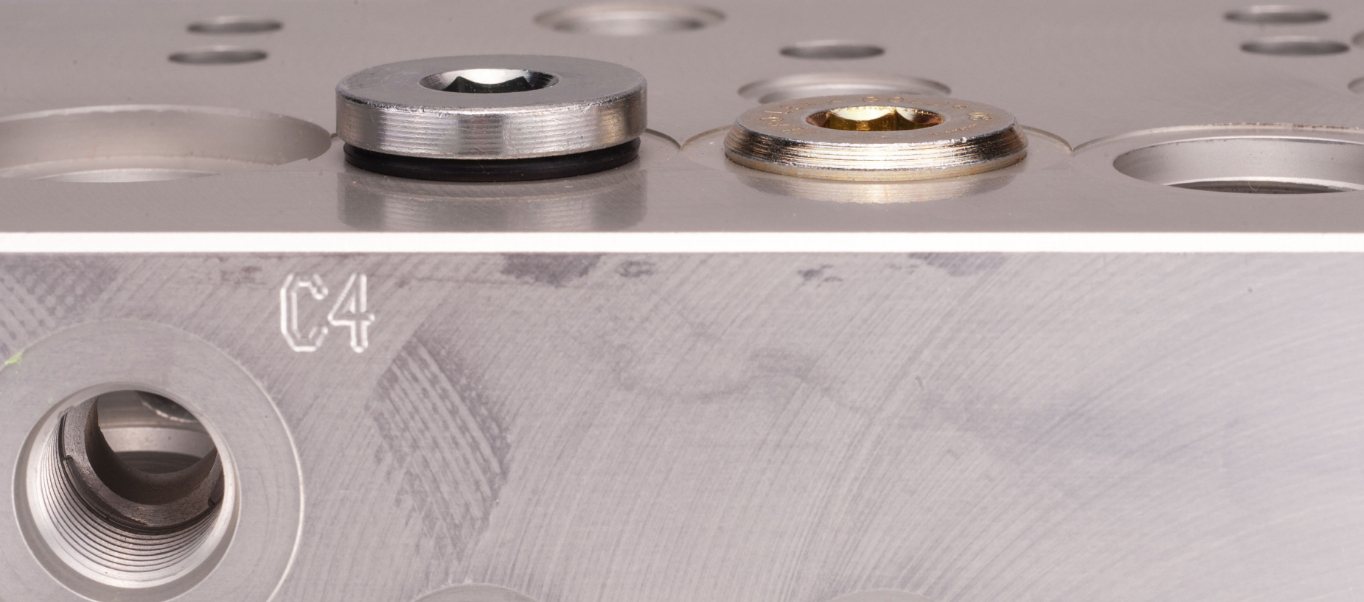

Zero-Leak Gold® plugs solve this problem at the source. They’re engineered to stay sealed under pressure, even in harsh environments with constant vibration and temperature shifts.

Here’s how Zero-Leak Gold® plugs outperform traditional alternatives:

- Metal-to-metal seal using a tapered thread and seat—no reliance on thread locking alone

- Self-locking design that resists loosening from shock, vibration, or thermal changes

- Interchangeable with standard SAE O-ring boss ports and other standard configurations

- Available in multiple plug styles: ORB plugs, SAE plugs, metric threaded plugs, and custom solutions

Choosing the Right Plug for the Job

Not all leak-free solutions are created equal. When selecting plugs for unused ports or maintenance applications, consider:

- Compatibility with existing hydraulic port standards (SAE, ISO, metric)

- Resistance to vibration and pressure cycling

- Ability to provide a long-term, zero-leak seal without regular re-tightening

- Easy installation and removal without galling or thread damage

Zero-Leak Gold® delivers on all of the above, making it a reliable and cost-effective upgrade for any hydraulic system prone to leakage.

Seal the System—Permanently

Whether you’re fighting leaks at the piston, port, or pipe, there’s no reason to settle for “good enough.” Upgrade to Zero-Leak Gold® plugs and fittings and eliminate common failure points before they become costly breakdowns.

Explore our full line-up of leak-proof hydraulic components and start building a more reliable, efficient system.